Stream - Industrial Fire-fighting Pumps - SEN40-250

Description

SEN series close coupled centrifugal pumps are with single impeller, which manufactured according to European standards EN733; SEN series are very extended: the different performances curves allow a right choice of the optimal model following all kinds of specific demands in several fields as: watersupply for living uses; industrial uses and general water plants projects; water supply;spray irrigations and watering, pressure sets, heating and air-conditioning plants, any other use for liquid decanting.

The pumps must be installed in enclosed places, or at least protected against inclement weather.

Pump Specifications

- Discharge flange diameter: DN32 – DN80 mm

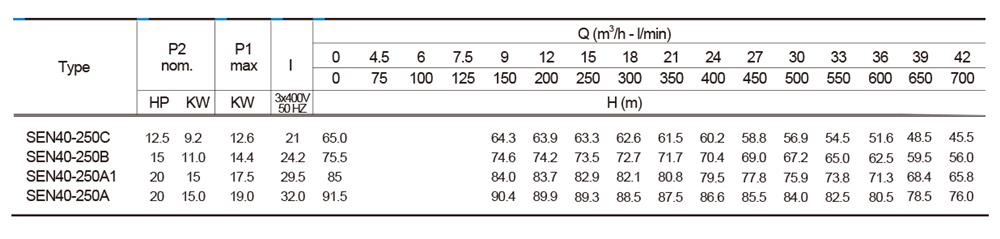

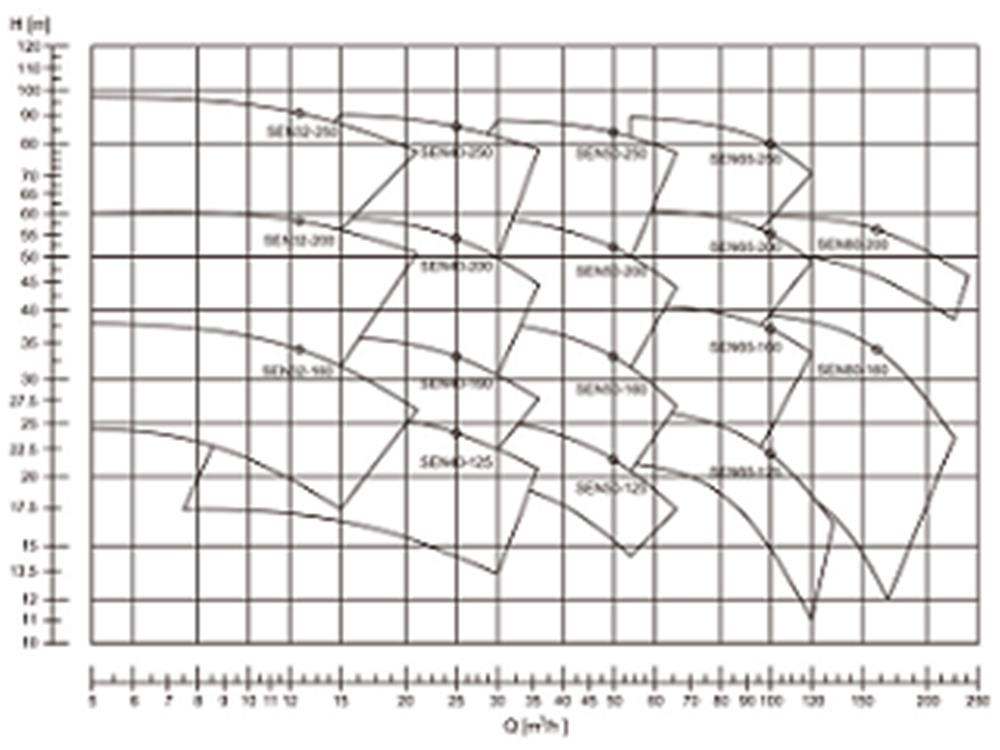

- Capacity Q range: 4.5m3/h - 240m3/h (50HZ)

- Head H range: 10m – 92.5m

- Operating speed: 2900RPM (50Hz)

On request:

- Other operating voltages and frequencies

- Special mechanical seal; special liquids

- Special temperature

Operation Conditions

- Working Temperature Range: -10? ~ +90?

- Max. Allowable Working Pressure(MAWP): 10bar

- Hydrostatic Test Pressure = 1.3 times the maximum discharge pressure, but not exceed 13 bar)

Motor Specifications

Totally Enclosed Fan Cooled a synchronous induction motor

Winding:

3 Phase 2 - 4 HP 220-240VD / 380-420VY - 50 HZ

3 Phase 5.5 - 50 HP 380-420VD / 660-725VY - 50 HZ

2 Phase 2 - 5.5 HP

- Degree of motor protection: IP55(IEC60034-5)

- Insulation Class: F

- Duty: S1 continuous duty operation

- Altitude shall not exceed 1000m above seal-level (IEC60034-1)

- Allowed air temperature between -20? and 40?(IEC60034-1)

On request:

Motor winding is protected with 3 PTCthermistors for tripping.

Construction Features

- Main dimensions: Apply to EN733 (DIN24255) standard and backpull out type

- Casing structure: End suction, center radial discharge

- Flange pressure rate: ISO7005.2 PN1.6MPa

- Shaft seal: Single mechanical seal(Graphite / Silicon carbide / Ceramic / NBR / FPM / SS304 / SS316) According to Standard EN 12756

- Driven shaft: Pump and motor flanged together to form a close-coupled unit, with common shaft.

Benefits:

- Advanced high efficiency design

- Reliability

- Distinguished heat dissipation

- Silence running

- Compact structure