Vanton - Sump-Gard Vertical Centrifugal Pumps - Sump-Gard SG

The industry standard for dependable thermoplastic vertical pump design

- Flows to 900 gpm (204 m3/h)

- Heads to 180 ft (55 m)

- Lengths to 20 ft (6.1 m)

- Temps to 275°F (135°C)

- Construction: PP, PVC, CPVC or PVDF

Vanton vertical thermoplastic sump pumps are engineered for dependable handling of corrosive, abrasive, hazardous and toxic process fluids and plant effluents over broad temperature and pH ranges. These rugged pumps are widely used for processing, environmental controls and water/wastewater treatment throughout the chemical, textile, pharmaceutical, pulp and paper, semiconductor, electroplating and other manufacturing industries, as well as in utilities and municipal water treatment facilities.

All fluid contact components are injection molded or fabricated of homogeneous polypropylene (PP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC) or polyvinylidene fluoride (PVDF) — corrosion resistant thermoplastics that are chemically inert to the fluids they are specified to handle. The heavy-duty stainless steel shaft is completely isolated from the fluid by a thick-sectioned thermoplastic sleeve. No metal is in contact with the pumped fluid, making these pumps additionally suitable for handling of high purity water, reagent grade chemicals, and other fluids that must remain contamination free.

The rugged construction of these heavy-duty sump pumps assures dependable service. Vanton's unique design automatically compensates for the different expansion rates between the metal shaft and plastic column. This prevents impeller binding even under wide temperature fluctuations. The solid, thick-sectioned thermoplastic wet end components are significantly lighter than metal, resulting in the ease of pump installation or removal and preventative maintenance.

In addition to conventional stationary installations, Vanton thermoplastic pumps can be skid mounted for portability within the plant, or floated on pontoons for use in open ponds.

Vanton offers the widest variety of thermoplastic vertical pump designs and configurations, and the most extensive experience in the industry. Our innovative engineering department is at your disposal to modify existing designs, or discuss entirely new configurations to meet your specific needs.

This pump available with recessed Vortex impeller for slurries and fluids containing stringy materials or solids to 2 in. (51 mm) in diameter.

Features

- Machined motor mounting bracket containing re-greaseable camlock ball bearings for positioning and locking pump shaft in position.

- Ball bearings act as thrust bearings and allow accurate adjustment of impeller clearance without removing pumps from installation.

- FUME-GARD® vapor seal minimizes emissions and protects external bearings and motor from corrosive fumes.

- Thermoplastic cover plate customized to meet tank/sump configuration.

- Thermoplastic columns structurally reinforced for additional strength when submerged shaft lengths are greater than 8 feet.

- Thermoplastic sleeve isolates the stainless steel shaft from the pumped fluid.

- The submerged inner wet bearing is made from ultra pure alumina ceramic, and the outer submerged bearing from Vanite®, pure silicon carbon. Clean process fluid or water is used to lubricate and cool the wet bearings.

- Injection molded or fabricated thermoplastic casing, casing cover and impeller.

- Thermoplastic closed or semi-open impeller injection molded with embedded dynamically balanced stainless steel insert keyed to shaft to assure positive drive. Vortex construction is available for handling slurries and solids laden fluids.

- Perforated strainer basket available in broad range of thermoplastic materials

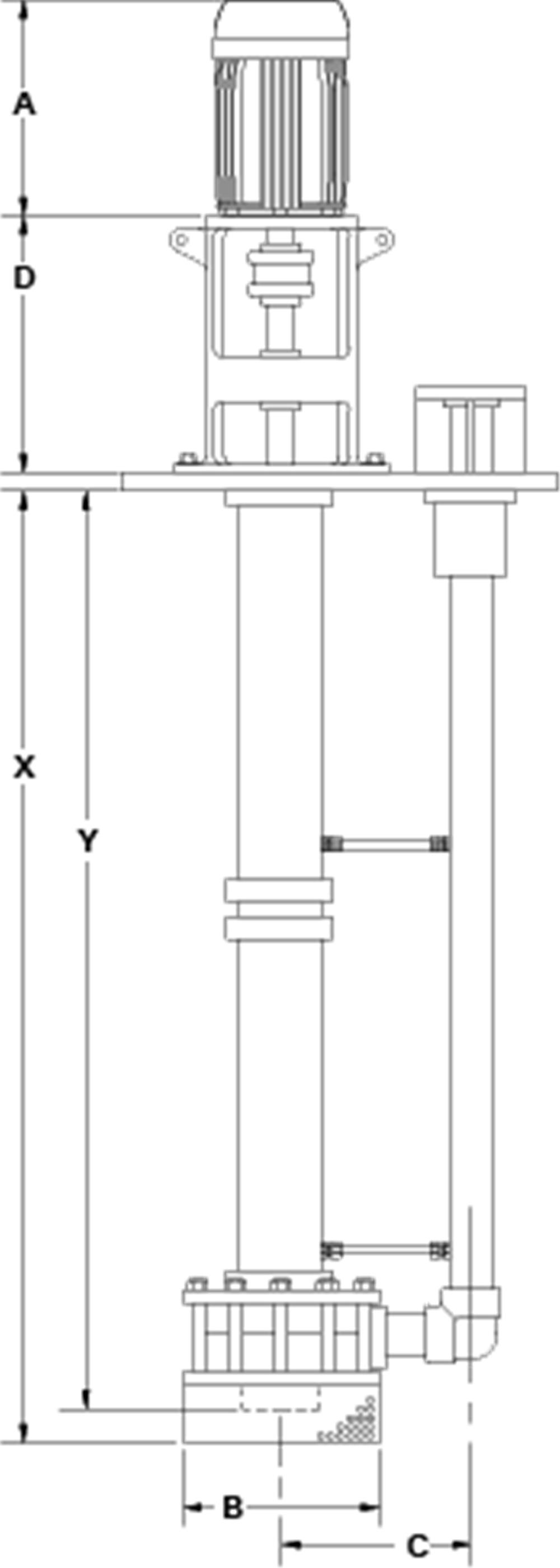

Dimensions

Scroll table left and right for small devices.

| MODEL | SIZE SUCTION / DISCHARGE |

DIMENSIONS IN INCHES (MM) | ||||

| A | B | C | D | Y/X | ||

| SG-200 | 1 X 1 (25.4 X 25.4) |

Varies with Motor Size |

9 (228.60) |

7 1/2 (190.50) |

10 1/2 to 12 3/8 (266.70 to 314.33) |

12 to 240 (304.80 to 6096.00) |

| SG-300 | 1 1/2 X 1 1/2 (38.1 X 38.1) |

11 1/4 (285.75) |

8 13/16 (223.74) |

10 1/2 to 12 3/8 (266.70 to 314.33) |

||

| SG-500 | 2 X 2 (50.8 X 50.8) |

11 1/4 (285.75) |

9 5/8 (244.48) |

10 1/2 to 12 3/8 (266.70 to 314.33) |

||

| SG-800 | 2 X 2 (50.8 X 50.8) |

11 1/4 (285.75) |

9 5/8 (244.48) |

10 1/2 to 12 3/8 (266.70 to 314.33) |

||

| SG-1000 | 3 X 2 (76.2 X 50.8) |

12 3/8 (314.33) |

9 5/8 (244.48) |

10 1/2 to 12 3/8 (266.70 to 314.33) |

||

| SG-1200 | 3 X 2 (76.2 X 50.8) |

15 (381.00) |

13 1/4 (336.55) |

18 1/16 (458.79) |

||

| SG-1800 | 4 X 3 (101.6 X 76.2) |

15 (381.00) |

13 1/4 (336.55) |

18 1/16 (458.79) |

||

| SG-2000 | 4 X 3 (101.6 X 76.2) |

15 1/2 (393.70) |

13 1/4 (336.55) |

18 1/16 (458.79) |

||

| SG-2400 | 6 X 4 (152.4 X 101.6) |

22 3/4 (577.85) |

17 1/8 (434.98) |

22 (558.80) |

||

*NOTE: Dimensions and specifications subject to change as indicated by ongoing product improvement program.