Stream - Industrial Submersible Motor - HN&HM

Description

HN&HM Series Water-filled Rewindable Submersible Motor

Operating Condition

- Installation position: Vertical.

- Surround Water Temperature: less than 30?

- Motor installing position in well: The depth of submergence less than 70M & the min.

- Distance to the bottom of well not be less than 5M.

- Duty: Continuous (S1).

- Max. Voltage Tolerance: +6%/-10%.

- Max. Frequency Tolerance: ±1%.

- Water quality: Sand content (weight ratio) in water should not exceed 0.01%, chlorine ion content should not be over 400mg/L.

- Water PH value:6.5~8.5

- Liquid Inside: Clean water or Anti-freezing mixture liquid filled into motor before operation.

- Min. cooling Water Flow: 20cm/s for motors up to 18.5KW and 50cm/s for the above.

- Starts per Hours: Max. 10 times.

- Service factor: 1.00 for motor in 50HZ and 1.10 for 60HZ

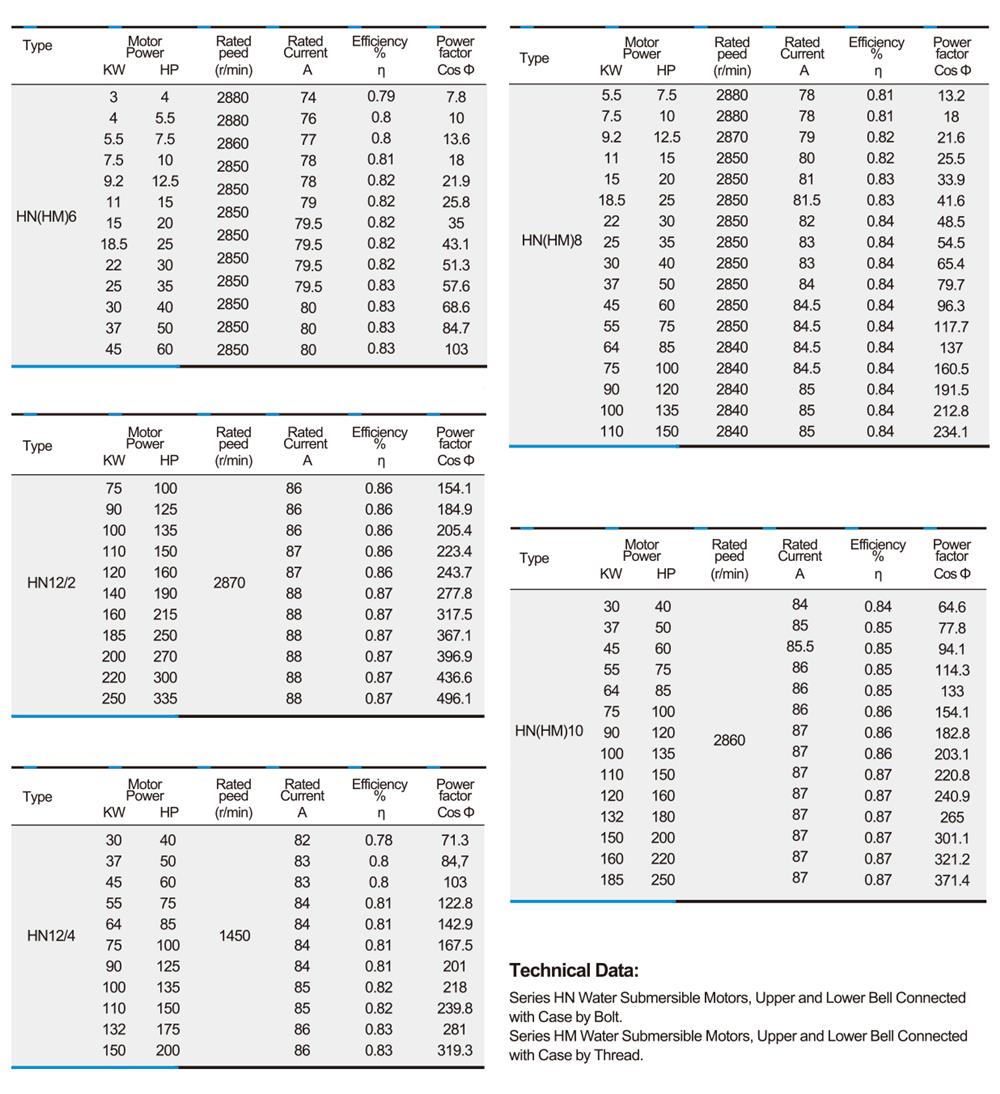

Technical data

- Series HN Water Submersible Motors, Upper and Lower Bell Connected with Case by Bolt.

- Series HM Water Submersible Motors, Upper and Lower Bell Connected with Case by Thread.

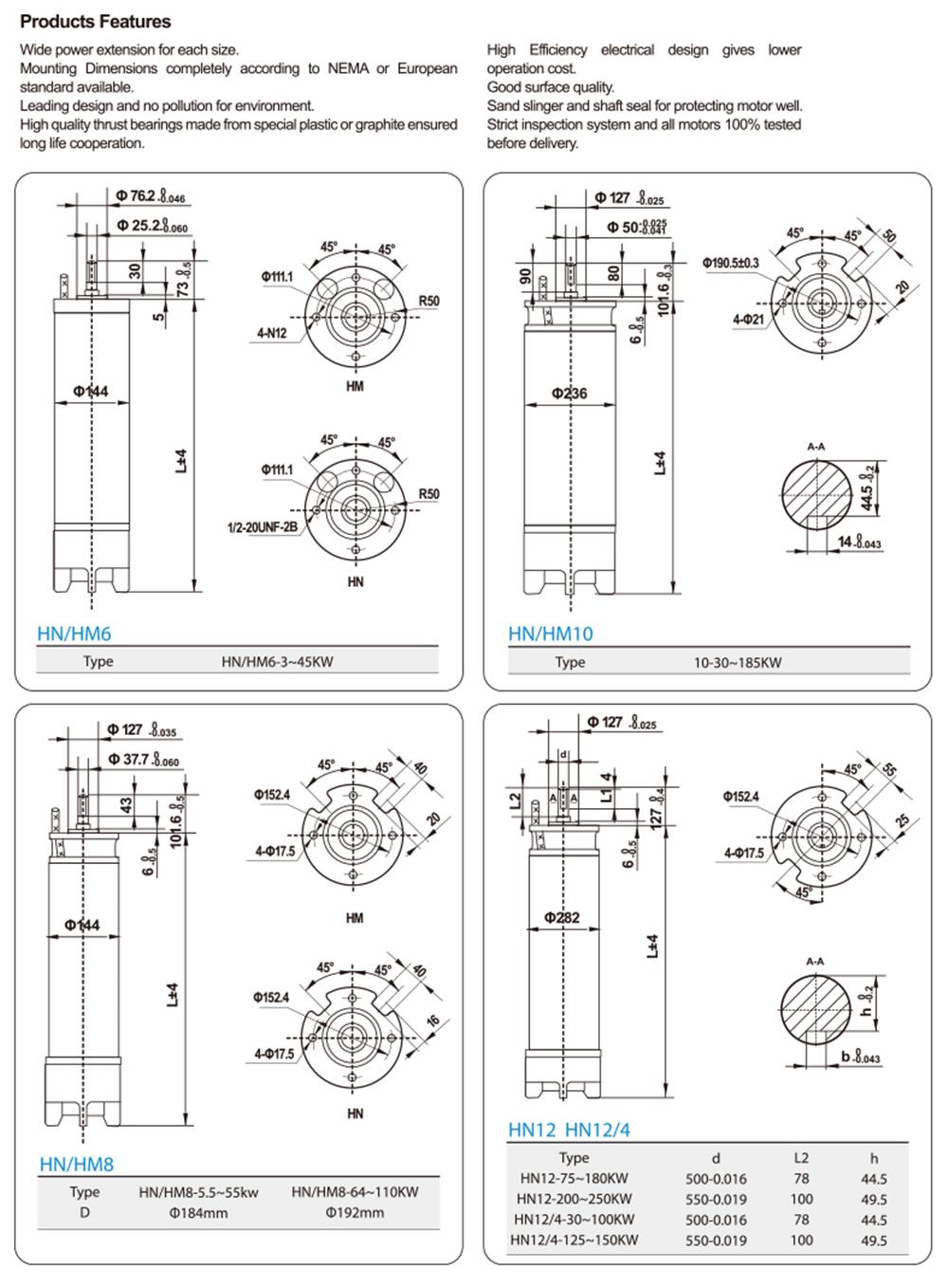

Products features

- Wide power extension for each size.

- Mounting Dimensions completely according to NEMA or European Standard available.

- Leading design and no pollution for environment.

- High quality thrust bearings made from special plastic or graphite ensured long life cooperation.

- High Efficiency electrical design gives lower operation cost.

- Good surface quality.

- Sand slinger and shaft seal for protecting motor well.

- Strict inspection system and all motors 100% tested before delivery