Vanton - Chem-Gard Horizontal Centrifugal Pumps - Chem-Gard CG

Horizontal Centrifugal Pumps for all-purpose handling of corrosive, abrasive and ultrapure liquids

- Flows to 900 gpm (204 m3/h)

- Heads to 185 ft (56 m)

- Temps to 275°F (135°C)

- Construction: PP, PVC, PVDF, ECTFE

Vanton CHEM-GARD® thermoplastic heavy-duty pumps are designed and constructed to maximize the unique properties of solid, homogeneous, chemically inert thermoplastics. Engineered to efficiently and safely handle corrosive, abrasive, and other aggressive fluids, Vanton pumps are also ideally suited to handle deionized and ultrapure water, pharmaceuticals, reagent grade chemicals and any fluid that must remain free from metallic contamination. Mechanical seals are reverse mounted to assure no metal-to-fluid contact.

Vanton injection molds casings, covers, and impellers from a broad range of homogeneous thermoplastics, ensuring that the wet end of each pump is chemically inert to the fluids — and resistant to the abrasives — it may encounter. These thermoplastics include: polypropylene (PP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinylidene fluoride (PVDF).

The wet end is comprised of solid, thick-sectioned, stand-alone components (unlike plastic linings), that are easily replaced, maximizing uptime while minimizing cost.

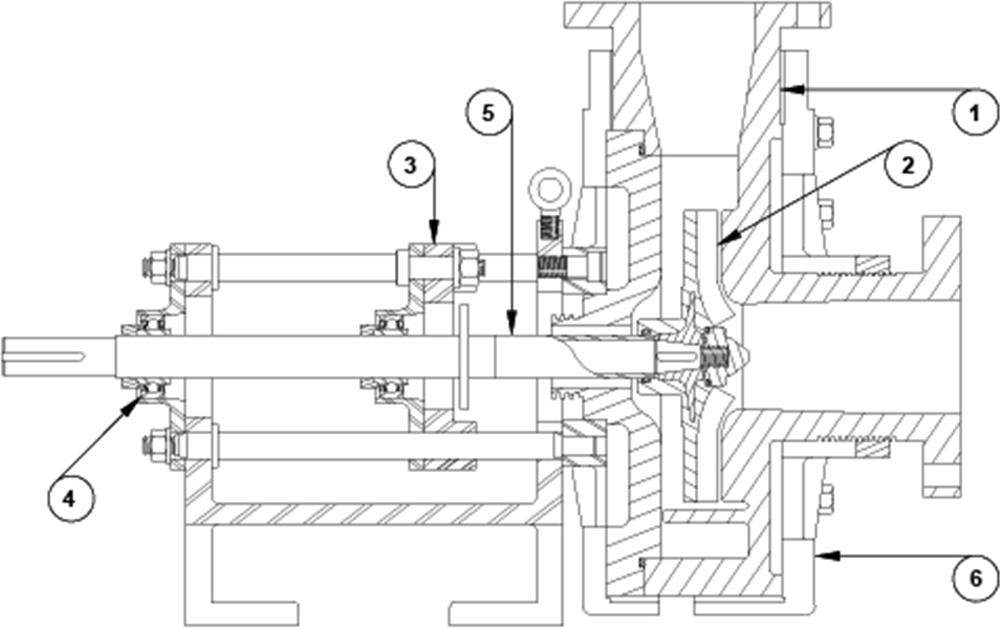

The unique, wide-open power frame design of CG, CGA and PG models features an adjustable front bearing that cuts maintenance by allowing easy inspection or resetting of mechanical seals without disturbing the piping. Mechanical seals are reverse mounted, limiting fluid contact to non-metallic surfaces. Because of the unique, wide-open power frame design, virtually any commercially available mechanical seal can be accommodated.

This award winning design allows the ability to position the inboard bearing immediately behind the mechanical seal, minimizing shaft deflection and impeller overhang. With thermoplastics typically being 80% lighter than metals, and coupled with the forward positioning of the inboard bearing, these rugged pumps with minimal shaft deflection and impeller overhang deliver vibration-free, corrosion-free performance and offer exceptionally long life with minimal maintenance.

Features

- Thick sectioned pump casing and cover are injection molded from homogeneous thermoplastics.

- Key driven, dynamically balanced injection molded impeller design with stainless steel insert ensures positive drive, provides additional rigidity to impeller at higher temperatures and pressures, and prevents damage in case of reverse rotation. Semi-open or closed impellers are available.

- The award winning wide-open power frame with a retractable inboard bearing assures minimal shaft deflection and impeller overhang and facilitates easy mechanical seal inspection and readjustment. The unique pedestal design allows for the use of most commercially available mechanical seals without the need for modification. Mechanical seals are reverse mounted, exposing only the non-metallic seal faces to the fluid handled.

- Heavy duty, self-aligning bearings widely spaced on the shaft, assures perfect alignment for maximum stability and long seal life.

- The relatively short, large diameter stainless steel shaft is sleeved with thermoplastic to isolate it from the fluid.

- External cast iron protective armor is completely coated with a chemical resistant, two-part epoxy paint to guard against chemical and atmospheric corrosion.

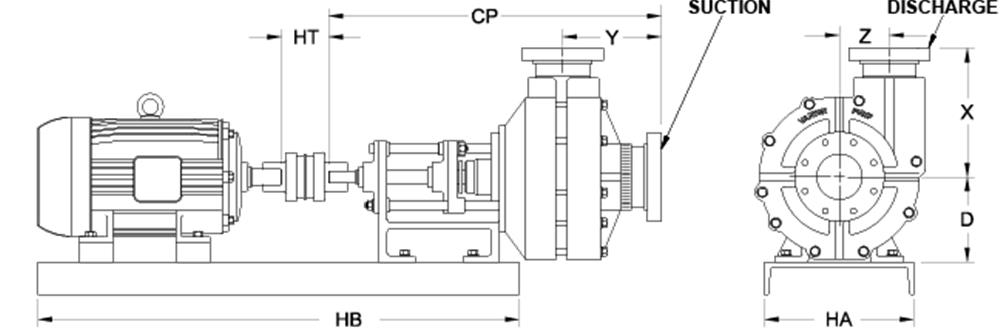

Dimensions

Scroll table left and right for small devices.

| MODEL | PUMP SIZE |

DIMENSIONS IN INCHES (MM) | |||||||

| CP | D | X | Y | Z | HA* | HT | HB* | ||

| CG-200 | 1 X 1 (25.4 X 25.4) |

22 15/32 (570.71) | 5 1/4 (133.35) |

6 7/8 (174.63) |

3 1/2 (88.90) |

2 1/2 (63.50) |

12 (304.80) |

1/2 (12.70) |

35 (889.00) |

| CG-300 | 1 1/2 X 1 1/2 (38.1 X 38.1) |

24 13/16 (630.24) | 5 1/4 (133.35) |

8 (203.20) |

5 (127.00) |

3 9/32 (83.34) |

12 (304.80) |

1/2 (12.70) |

35 (889.00) |

| CG-500 | 2 X 1.5 (50.8 X 38.1) |

25 5/16 (642.94) |

5 1/4 (133.35) |

8 (203.20) |

5 (127.00) |

3 9/32 (83.34) |

12 (304.80) |

1/2 (12.70) |

35 (889.00) |

| CG-800 | 2 X 1.5 (50.8 X 38.1) |

25 1/4 (133.35) |

5 1/4 (133.35) |

7 15/16 (201.61) |

4 15/16 (124.41) |

3 9/32 (83.34) |

12 (304.80) |

1/2 (12.70) |

35 (889.00) |

| CG-1200 | 3 X 2 (76.2 X 50.8) |

27 1/4 (692.15) |

5 1/4 (133.35) |

10 3/4 (273.05) |

7 (177.80) |

4 3/16 (106.36) |

12 (304.80) |

1/2 (12.70) |

41 (1041.40) |

| CG-1800 | 4 X 3 (101.6 X 76.2) |

27 1/4 (692.15) |

5 1/4 (133.35) |

10 3/4 (273.05) |

7 (177.80) |

4 3/16 (106.36) |

12 (304.80) |

1/2 (12.70) |

41 (1041.40) |

| CG-2400 | 6 X 4 (152.4 X 101.6) |

36 7/16 (925.51) |

10 1/4 (260.35) |

16 (406.40) |

12 (304.80) |

Centerline Discharge |

15 (381.00) |

1 (25.4) |

60 (1524.00) |

*Baseplate dimensions will vary with motor frame size.

All dimensions are approximate and not to be used for construction purposes.